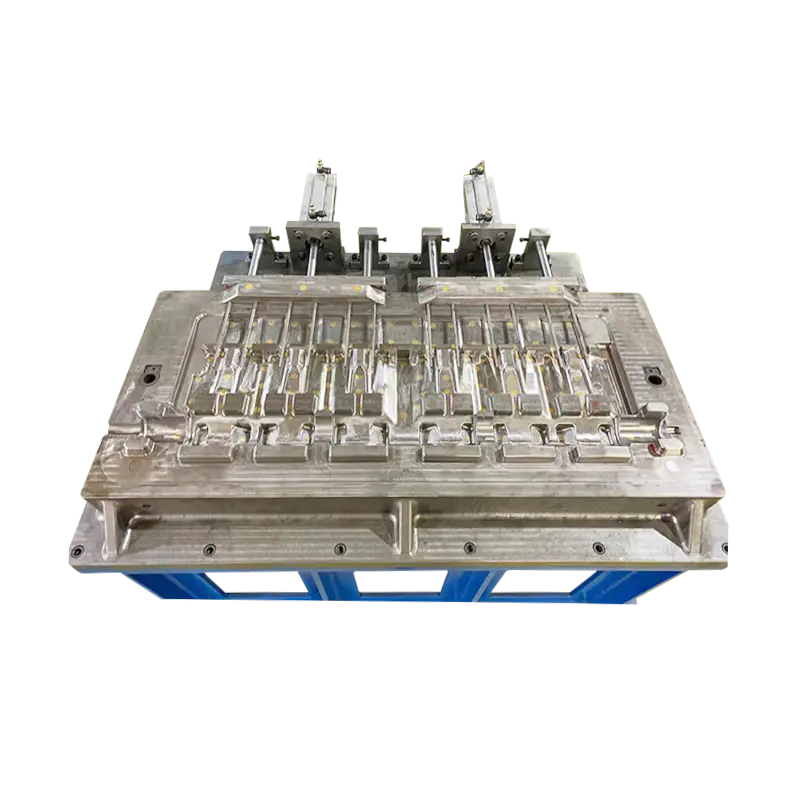

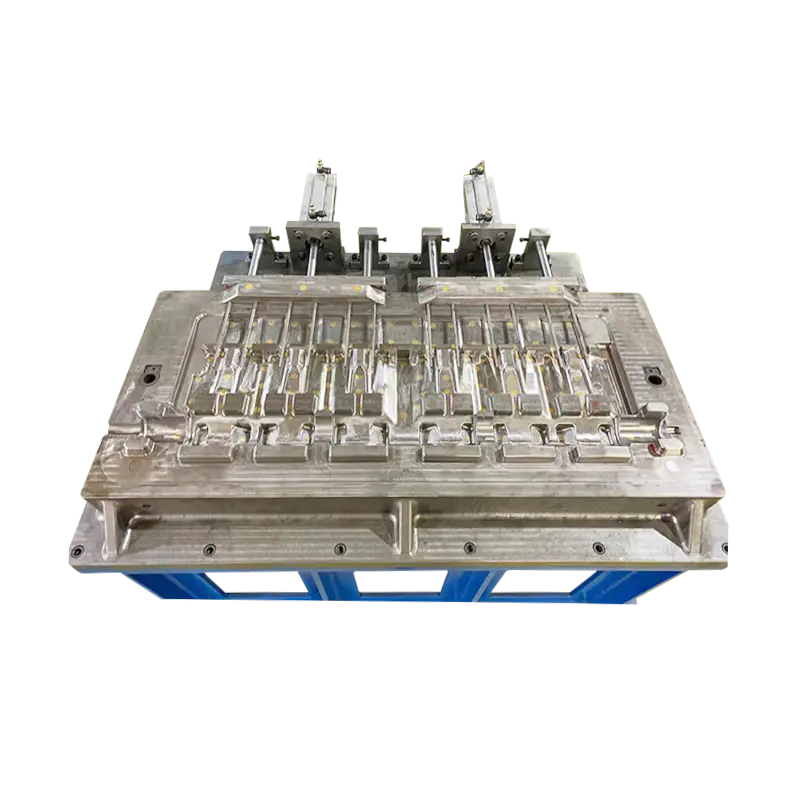

There should be various criteria for judging the quality of die-casting molds, including:

1. Whether the dimensional accuracy can be carried out within the tolerance requirements of zinc alloy die castings.

2. The production efficiency of die casting, that is, the time required for die casting products.

3. The reliability of the mold, the die-casting mold can always maintain high-quality products.

4. The life of the die, the die-casting die can generally release 100W sets, which is far below this value and is not a qualified die-casting die.

5. The flow channel design of the die-casting mold ensures that the die-casting product will not have defects such as flow marks and fractures.

6. Whether the die-casting mold design is reasonable. This rationality includes the rational design of the die-casting die structure, the correct design of the nozzle position, the strength of the die-casting die within the required range, and the reasonable arrangement of the die-casting die cooling water path, which is conducive to the iron core being pulled out of the zinc alloy die-casting. Slime mold. These require years of experience in mold design. Shenzhen Yuge has several senior mold masters who can quickly design die-casting molds, the mold opening cycle is 10-15 days, there are fewer mold problems, and the processing speed is faster.

Pусский

Pусский Español

Español