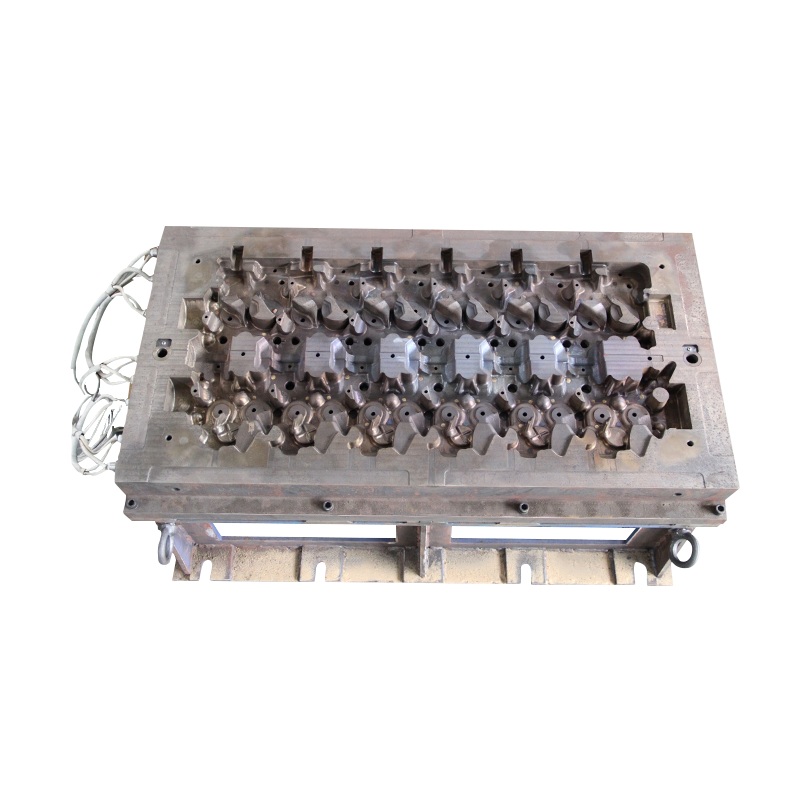

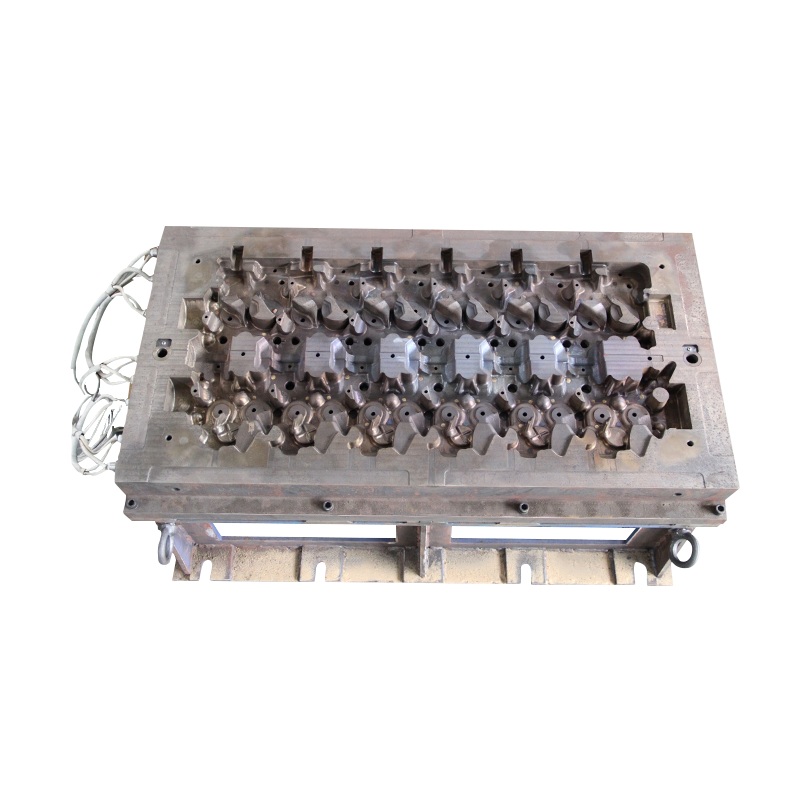

A cylinder head mold is a tool used in the manufacturing process of cylinder heads for internal combustion engines. A cylinder head is a key component of an engine that sits atop the cylinders and helps to seal the combustion chamber. It contains the spark plug, intake and exhaust valves, and other components that are used to control the flow of air and fuel into the cylinder and exhaust gases out of the cylinder.

A cylinder head mold is a specialized tool used to shape and form the cylinder head from raw materials, such as aluminum or iron. The mold is typically made of metal or another durable material and consists of two halves that are held together under pressure to form the shape of the cylinder head. The mold is designed to create the precise shape and size of the cylinder head to ensure that it fits properly with the rest of the engine.

Cylinder head molds are typically used in conjunction with casting or forging processes to produce cylinder heads. The raw material is heated to a high temperature and then poured or pressed into the mold, where it is allowed to cool and solidify. The finished cylinder head is then machined and finished to the desired specifications. Cylinder head molds are an essential tool in the manufacturing process of internal combustion engines and are used to produce cylinder heads for a wide range of applications.

A hot core box-water jacket core mould is a tool used to create a hot core box-water jacket core, which is a type of heating element. It is typically made of a heat-resistant material such as metal or ceramic and is designed to withstand the high temperatures that the hot core will reach during operation. The mould is used to shape the hot core and the water jacket into the desired shape and size, and may also include features such as channels or ports to allow for the circulation of water through the jacket. The mould may be used in conjunction with other manufacturing processes, such as casting or machining, to create the finished hot core box-water jacket core.

Pусский

Pусский Español

Español