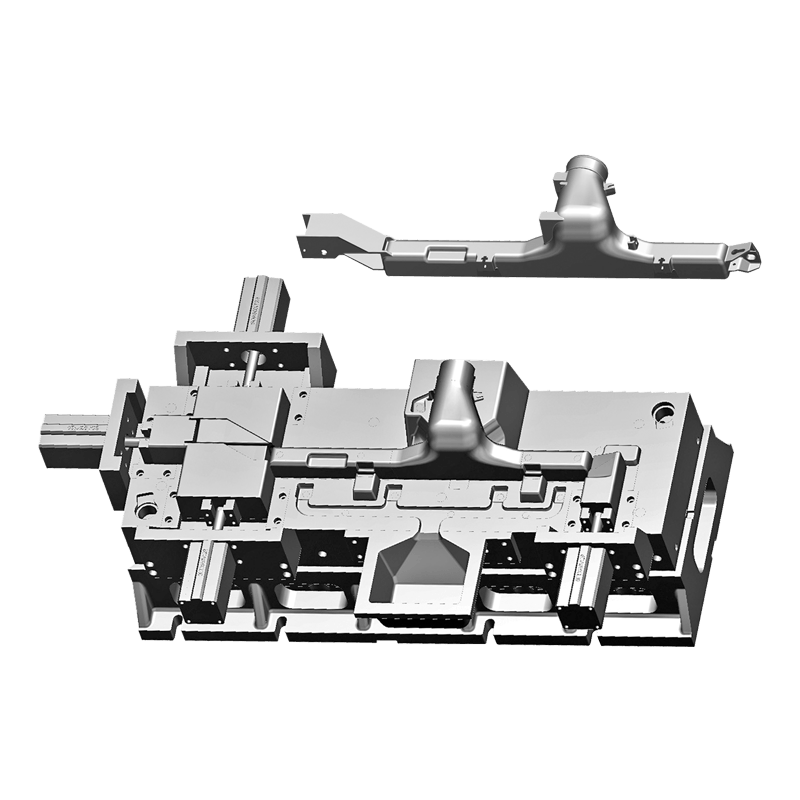

An exhaust pipe mould has a cavity, cross gate and water gaps to form a complete exhaust pipe. Each of these components is connected to the mould cavity by a riser. The mold is then beaten at the fitting positions of the individual parts to form the finished exhaust pipe. The mold's main design focuses on maximizing yield and quality.

Determine the correct flow direction and material. The direction of flow is important as an incorrect placement or processing can cause negative dimensional accuracy and mechanical strength. The flow direction and material flow are represented in Table 3.20. If the pipe is not flowing properly, the material will be distorted or the end product will have poor mechanical strength. In such cases, you can increase the temperature of the mould or reduce the clamping force. You can also increase the gap between the pieces in the mould to avoid these problems.

Ensure a high-quality mold. Exhaust pipe moulds must be manufactured to the highest standards of quality. These parts are often intricately crafted and feature many complex structures. Therefore, processing precision for the internal cavity of a mould is extremely high. Modern technology has also been making its way into the automotive industry.

An exhaust pipe mould consists of an injection die holder and a limiting groove. The mold core is installed in the upper part of the mold. The exhaust piece is then inserted inside the front part of the mould. A slide bar and spring are installed below the exhaust piece. The gas guide groove and the flow dividing head are both fixed to the mold core. They form an integral structure. This prevents the pipes from being twisted during the molding process.

Choosing a quality exhaust pipe mould is important. Poor mold exhausts create large back pressure which prevents rapid filling of the mold. The process is prolonged and the pressure holding time increases. Injection parts lose efficiency due to poor exhaust. Corrosive gases also build up on the cavity's surface. These corrosive gases also reduce the life of the mould under normal use. There are some important aspects to consider when selecting an exhaust pipe mould.

Pусский

Pусский Español

Español