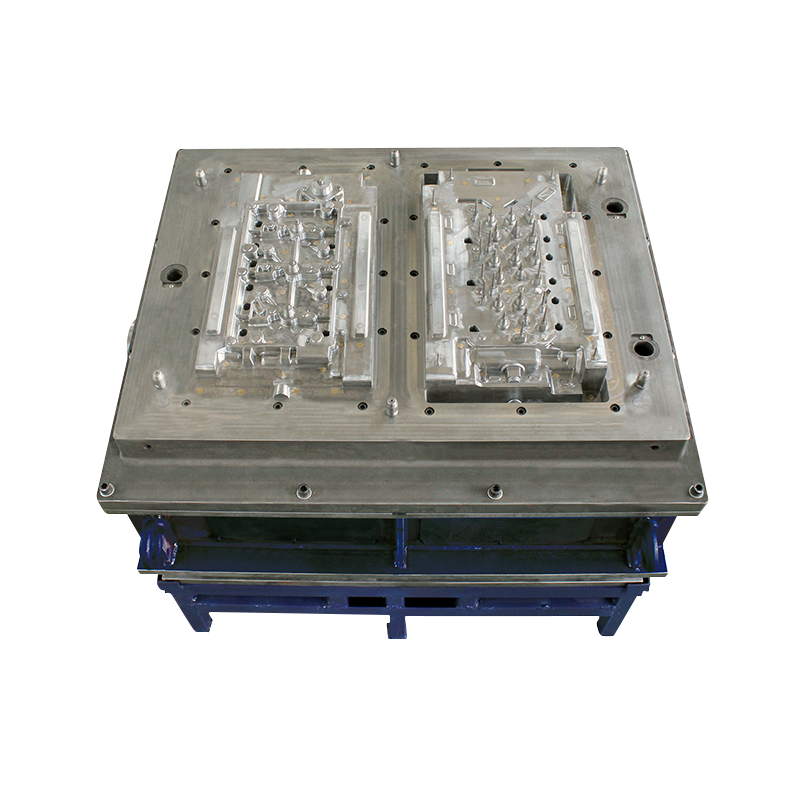

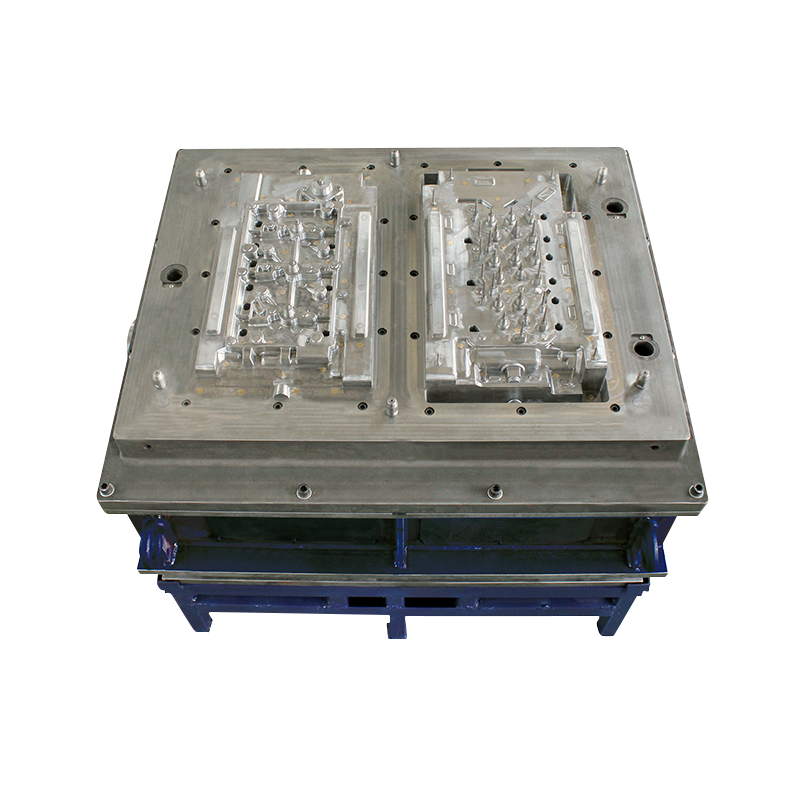

The Gravity casting mold is a mold that is used for casting crankshafts. The mold has an openable cavity that conforms to the shape of the crankshaft 10. The mold also has a pouring gate or passage through which the molten metal can flow upward. Once the casting is finished, it is removed from the mold.

Gravity casting molds are made of steel or aluminum. Unlike other methods, this one is used to create hollow castings. Typical casting metals include aluminum, magnesium, and tin alloys. However, this method also allows for the casting of iron alloys. Typically, the mold is preheated to about 150 to 200 degrees before the metal pours into it. This is done to minimize thermal damage.

Another benefit to gravity casting molds is their durability. Since gravity casting requires minimal finishing, a gravity casting mold can be used time again for similar parts. This is especially useful for manufacturing parts with intricate shapes and in high volume production runs. It is also inexpensive to produce. The molds can be reused many times, which can result in significant savings.

A counter-gravity casting shell mold contains a drag and a resin-bonded sand. The drag and cope are sealed together to create a sealing surface. The drag and cope are attached to each other through a parting line inside a vacuum chamber. A shell mold is also commonly referred to as a thin-walled mold, but there is no set definition. The mold hardens by a chemical reaction, heat, or catalysis.

Once the mold is coated, the molten metal is poured into it. The metal is then forced into the mold cavity by a high-pressure mechanism. This process lasts until the casting is solid. After it is finished, the casting is removed from the mold to prevent hot tears. A properly-coated mold should last for several castings.

Gravity casting molds can be made of any metal or alloy. Aluminum alloys are popular for gravity die casting because they are strong, lightweight, and corrosion-resistant. Copper alloys are also excellent for gravity die casting. They are strong and highly resistant to wear and are almost as tough as steel. You can find a great variety of these types of molds in China.

Pусский

Pусский Español

Español