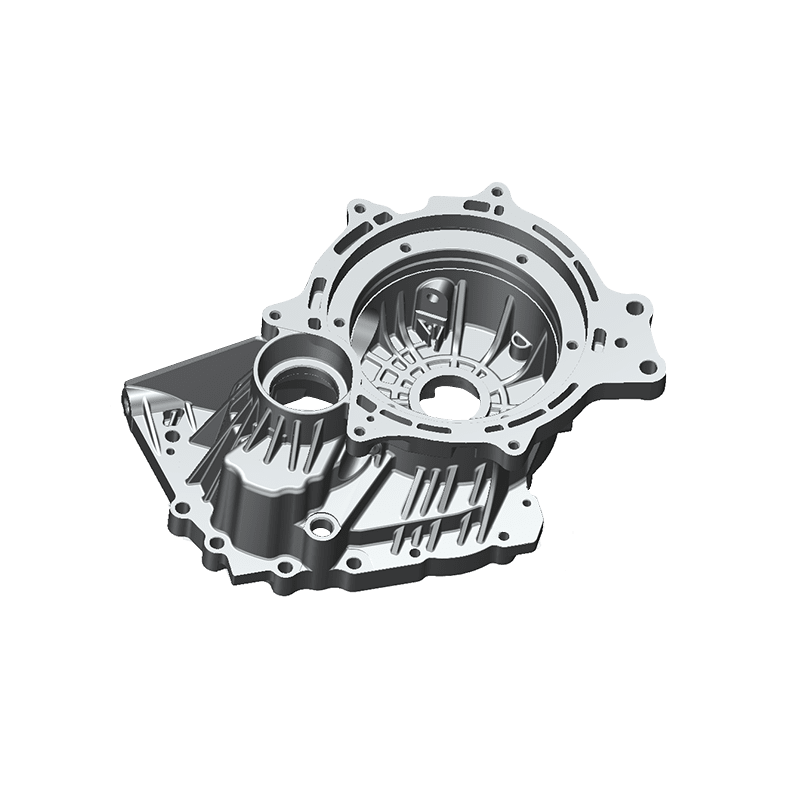

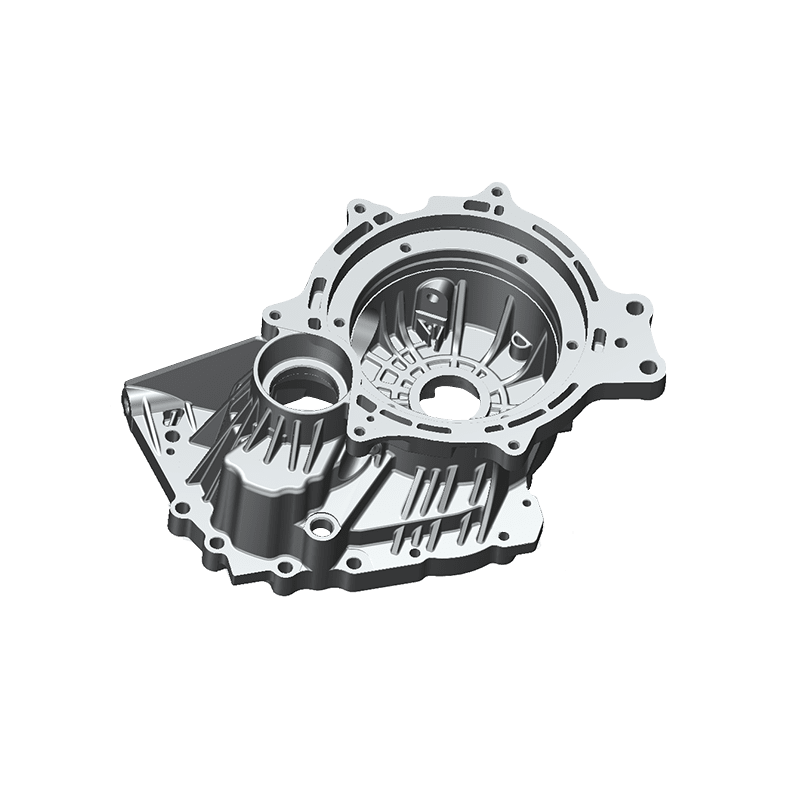

Engine parts moulds play a vital role in the automotive industry, enabling the efficient and precise manufacturing of engine components. These moulds are essential for producing engine parts with consistent quality, dimensional accuracy, and durability.

Precision Manufacturing:

Engine parts moulds are engineered with precision to ensure the accurate replication of complex engine components. These moulds enable the production of intricate parts with tight tolerances, such as cylinder heads, pistons, engine blocks, and intake manifolds. The use of advanced moulding techniques, including injection moulding, die casting, or compression moulding, allows for precise shaping and forming of the materials, resulting in components that meet strict design specifications.

Consistent Quality and Durability:

Engine parts moulds contribute to maintaining consistent quality and durability in engine manufacturing. By using high-quality moulds, manufacturers can achieve uniformity in the finished products, ensuring reliable performance and longevity. The precise moulding process eliminates variations in dimensions and material properties, reducing the risk of defects and ensuring consistent functionality across engine parts.

Advancements in Moulding Technology:

The field of engine parts moulds has witnessed significant technological advancements. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software enable the precise design and simulation of moulds, enhancing the manufacturing process's efficiency and accuracy. Furthermore, the use of advanced materials for mould construction, such as hardened steels or high-performance alloys, improves the moulds' durability and longevity. Additionally, the integration of automation and robotics in moulding processes enhances productivity and reduces manual labour requirements.

Pусский

Pусский Español

Español