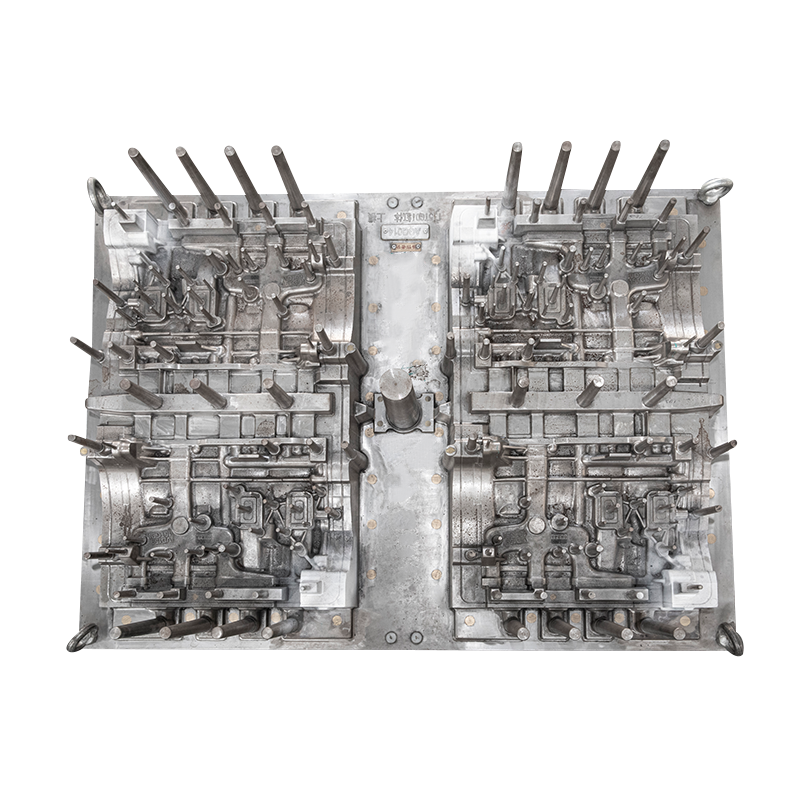

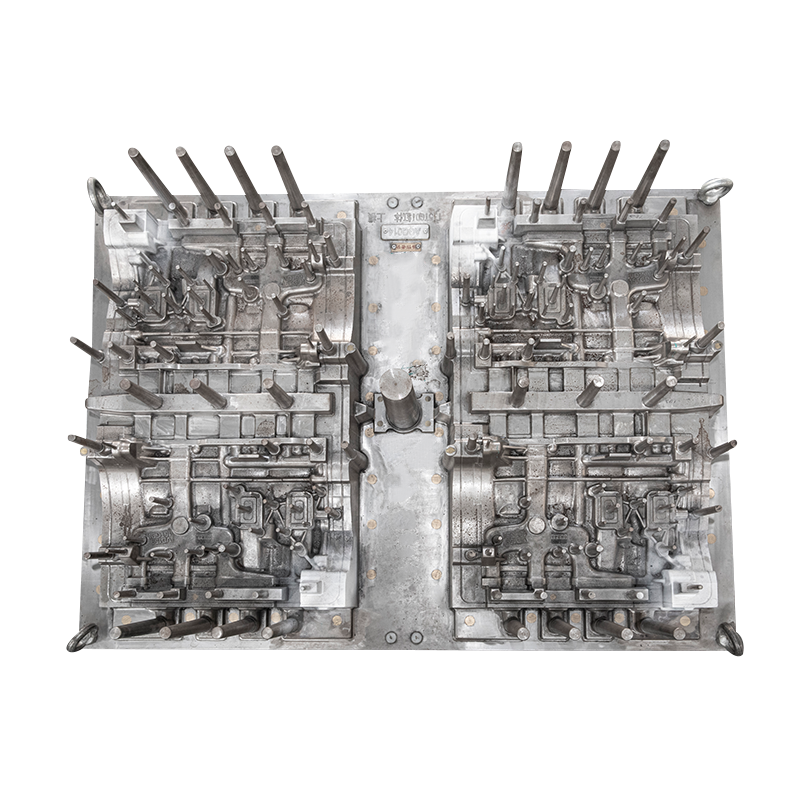

A gravity casting mold is a multi-piece device with an exhaust runner core, twin-scroll part, sub-gate core, and main gate core. It is used in the manufacture of car parts. These molds are also useful in the manufacturing of motorcycle parts. Here are some advantages of the gravity casting mold. These molds are highly durable and can be reused several times. To ensure that they will last for years, they are made with high-quality materials and are built to withstand the rigors of mass production.

A gravity casting mold is made of male and female tooling. The molten metal is poured into the mold cavity, where it hardens by gravity. To produce a high-quality part, non-ferrous alloys with low melting points are best. Higher-melting-point alloys can cause the mold to break down faster. Therefore, it is advisable to use non-ferrous alloys in gravity casting molds.

A gravity casting mold is a suitable option for making motorcycle hubs made of aluminum alloy. This mold consists of two molds-a lower one and an upper one. It has a sand core and is connected to a forming mold. It is characterized by an aluminum water injection straight pouring gate extending downward. A cross pouring gate connects the sprue with the upper gate and forms a buffering angle with it.

Using a gravity casting mold for aluminum alloy motorcycle hubs can help reduce production costs. The tool is designed to minimize the number of casting defects such as including slag, oxide skin, and middle hubs. This also means fewer lost oil paints. And gravity casting molds are easy to reuse. It's worth noting that gravity casting molds are not cheap. And gravity casting is still considered a high-quality part.

A gravity casting mold consists of two parts-the first and second mold, and an exhaust runner mold. These three pieces together form a turbine housing cavity and a twin-scroll part. The first riser contains a heating sleeve, which prevents the molten metal from shrinking in the twin-scroll part. The upper end of the second riser contains a sprue cup for maintaining the proper temperature of the molten metal.

Pусский

Pусский Español

Español