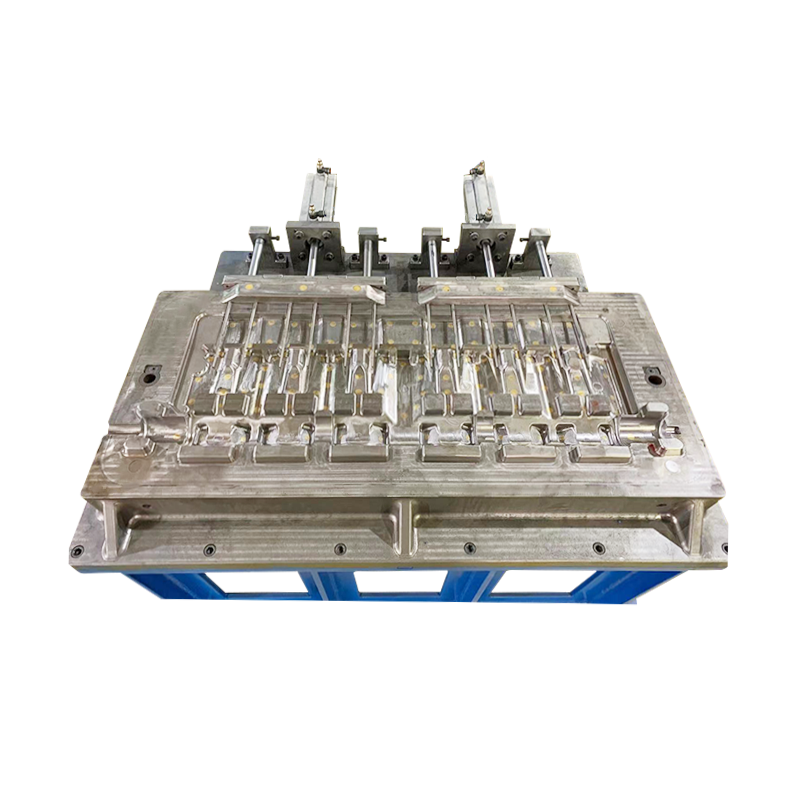

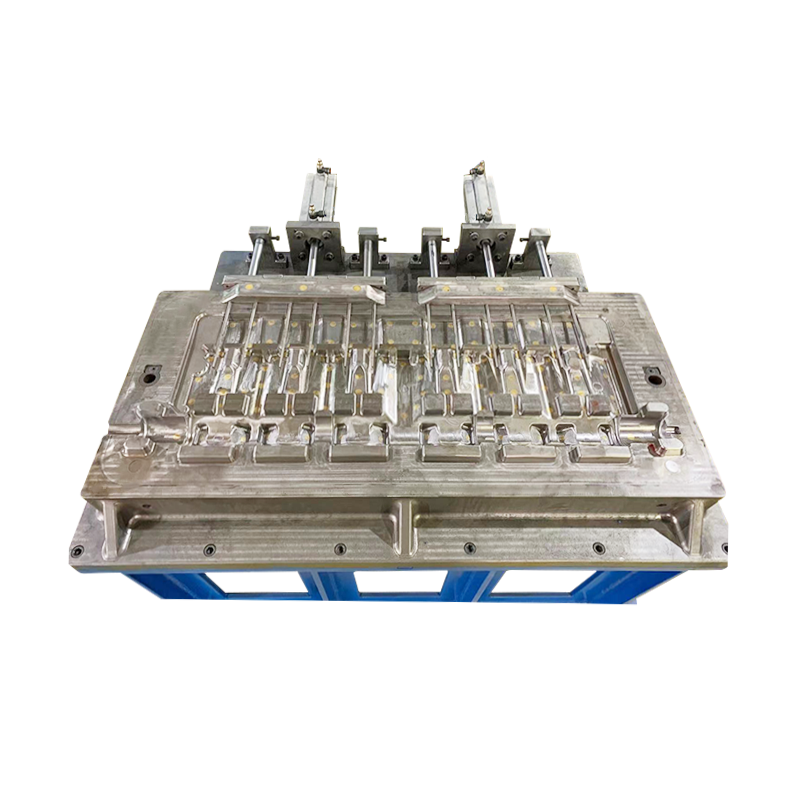

The cylinder block mold is used in the casting of a cylinder for an internal combustion engine. It comprises an integral cylinder liner and a cast body portion. The two components are mounted to a first and second core unit. The first core unit is made of reducible material and includes the main core portion partially occupying the bore and a port extending through it.

A second cylinder core unit can be molded separately and then assembled to the first molded core assemblage. These two components are then joined together to form a complete cylinder.

A cylinder block mold package can include several different individual cores, including an integral barrel-crankcase core and cylinder bore liners. It can also include various internal cores, such as end and side cores. It is also possible to include a water jacket slab core. These cores must be placed in the mold and hold them in place with cement. The mold package should include at least 21 cores, which is the minimum number required for a single cylinder block.

The individual cores of a cylinder block mold package are assembled on a temporary base that will not be part of the final engine block mold package. The assembled core package is then separated from the temporary base and cleaned with high-pressure air. The final mold package includes the base and cover cores.

The cylinder block is the most critical casting on an engine. Its wall thickness is typically less than 3mm. The most popular cylinder casting material is wet clay sand. This material offers good forming and a low energy and noise profile. The molds used in this manufacturing process are air-punching and static pressure molding lines. The technology in these molding machines is continually improving, so that the process is highly efficient.

Pусский

Pусский Español

Español