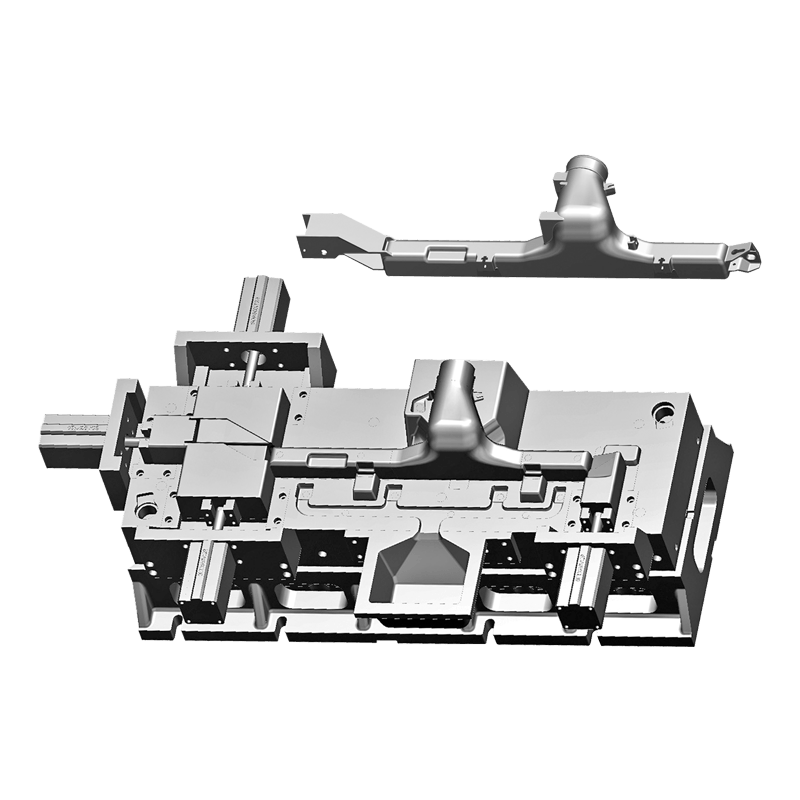

Generally speaking, an exhaust pipe mould is used to produce exhaust pipes for motor vehicles. Exhaust pipes play an important role in the construction and installation of motor vehicles. They have a complicated structure and a variety of functions. Some of the functions include: reducing vibration, improving quality, extending the lifespan of the exhaust system, and facilitating installation. Exhaust pipe moulds are characterized by a complex structure and a large number of small welds. Therefore, determining the position and direction of the exhaust system is important. The position of the exhaust system can affect the dimensional accuracy, mechanical strength, and quality of the final product. In addition, the improper position can cause defects during the processing process.

An exhaust pipe mould consists of the mold cavity, water gaps, and a cross gate. The cross gate is placed across the mold cavity, and the water gaps are connected to the mold cavity through a riser. The riser is arranged at the joint of the cross gate and each water gap. The upper wall surface of each water gap is an inclined plane. The upper wall surface of the water gaps prevents impurities from entering the mold cavity.

A mold that is designed with an insert can prevent failure of an exhaust pipe mould. An insert can be placed in the recesses and discharge the trapped air when the material flows to the points. The insert can also discharge the trapped air along the fitting position. This can prevent the formation of sleepy gas and the failure of the mold. Using an insert can also improve the processing efficiency and ease the maintenance of the mold.

An exhaust pipe mould has a complex structure and requires a special insert to discharge the trapped air. Hence, the process insert design is used for exhaust systems that need large quantities of exhaust. In the process insert design, the insert structure is designed to fit along the fitting position of the small insert head.

The process insert design is usually used when the size and exhaust requirements are great during the injection molding process. Its performance can be compared with a ready-made insert. However, the process insert design is usually used for special products.

Pусский

Pусский Español

Español