Matters needing attention in the production of aluminum alloy die castings:

1. Wall thickness, the gap of thickness will affect the replenishment;

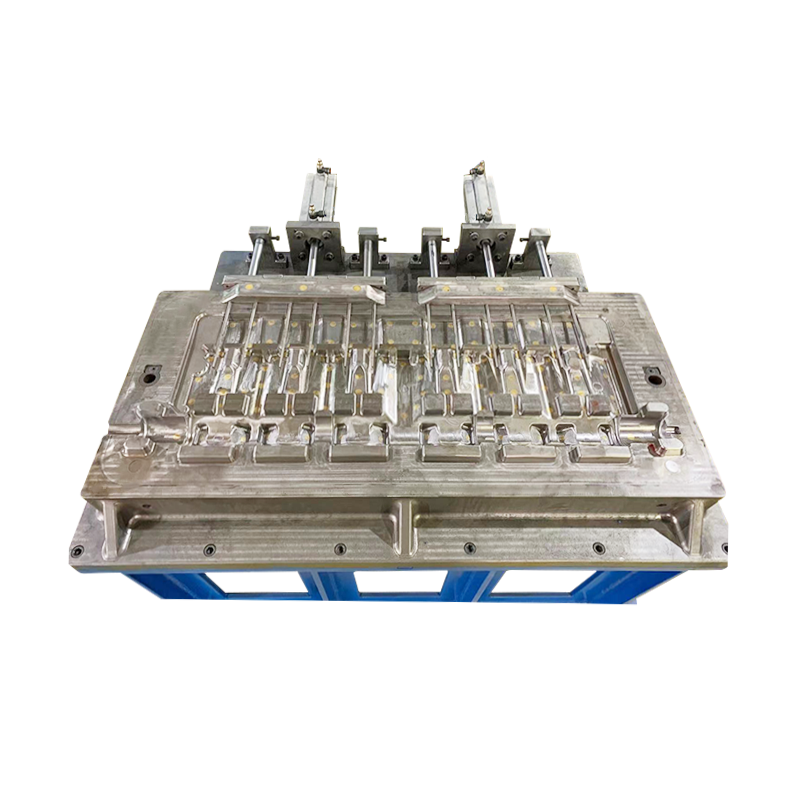

2. Demoulding, which is much more difficult than injection molding demoulding, so special attention should be paid to the setting of the draft angle and the demoulding force. Usually, the draft angle is 1~3 degrees, considering the smoothness of demolding, The slope of the external draft is smaller than that of the internal draft, the external draft is 1 degree, and the internal draft is 2~3 degrees;

3. In The mold, if there are multiple directional pumping positions, even if the two ends are placed, it is better not to place the lower pumping center, as the lower pumping center will cause cracks;

4. Some aluminum alloy dies castings will have other regulations, such as oil injection, powder spraying, etc. At this time, it is necessary to avoid the gate overflow groove to facilitate the setting;

5. Prevent complicated mold cloths in layout, and cannot use multiple cores or spiral cores;

6. Stop the external processing. It is necessary to leave the processing amount in the whole machine planning. , it's time for sparks on the mold. It is better to leave no more than 0.8mm, and no pores can be seen on the processed surface because it is protected by a hard layer;

7. Aluminum alloy die-casting parts are not elastic, and the buckle position should be the same as that of plastic;

8. Do not make deep holes on weekdays, only make some holes when opening the mold, and then process it;

Pусский

Pусский Español

Español