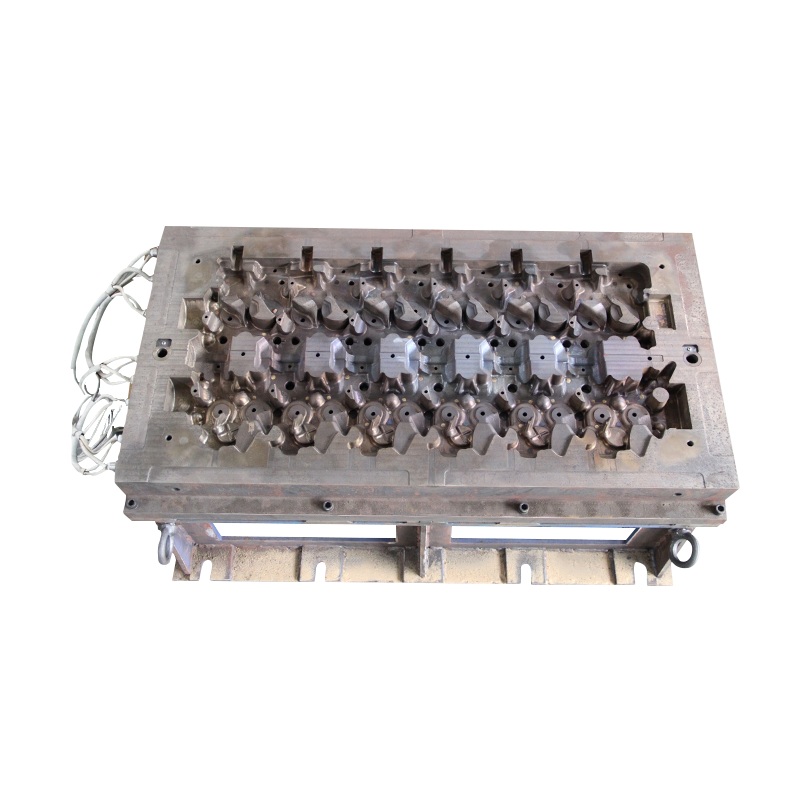

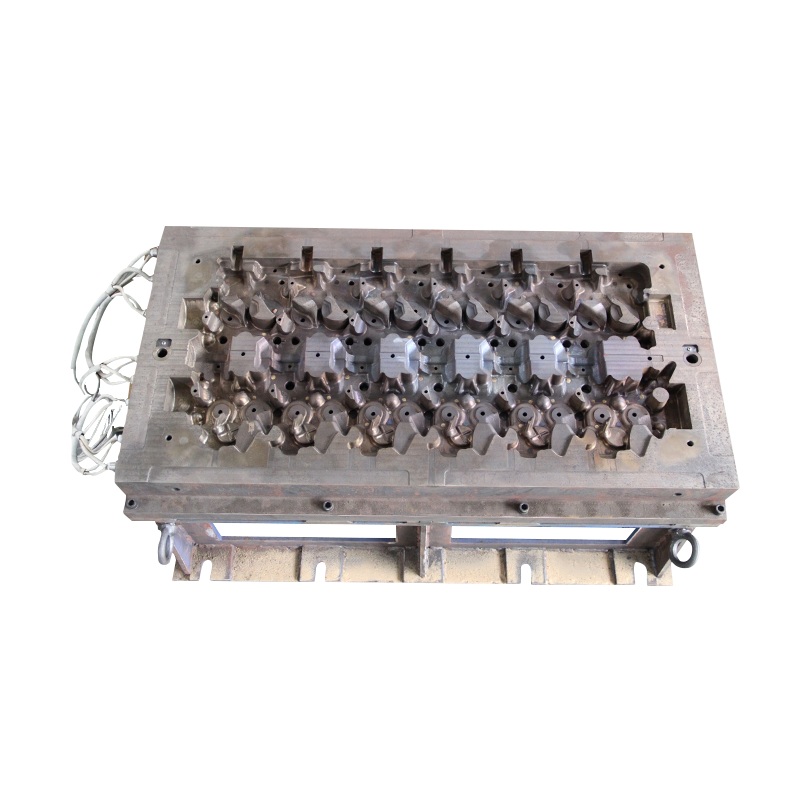

Die-casting is a kind of pressure casting part. It uses a pressure-casting mechanical die-casting machine equipped with a casting mold. The metal such as copper, zinc, aluminum, or aluminum alloy heated to a liquid state is poured into the feeding port of the die-casting machine. Die casting, casting copper, zinc, aluminum parts, or aluminum alloy parts of the shape and size limited by the mold, such parts are often called die castings.

Compared with ordinary workpieces, die castings have the following 7 advantages:

1. Die castings have high precision, stable dimensions, good consistency, and small machining allowances.

2. Capable of die-casting threads, lines, texts, pictures, and symbols: the die-casting filling process is always carried out under the effect of pressure and shapes such as peaks and valleys, convex and concave, and narrow grooves can be clearly die-casted. Therefore, die casting can press out very clear threads, lines, words, pictures, and symbols.

3. Die-casting parts can be treated with coating surface: due to the increasing use of die-casting parts, the surface of die-casting parts can be coated and surface-treated in order to meet the needs of users, such as electroplating, anodizing, polishing, organic maintenance coating. coating, painting, sandblasting, pickling, etc. Then comes the decorative or maintenance needs.

4. The use of the insert casting method in the die-casting mold can save the installation process and simplify the production process: parts of other materials (such as steel, iron, copper, alloy, aluminum, etc.) can be embedded in the die-casting parts to save valuable materials. and processing man-hours, and can obtain parts with complex shapes and parts with excellent performance.

5. The die-casting parts are densely arranged and have high strength and hardness: because the liquid metal is rapidly cooled in the die. At the same time, it crystallizes under pressure, so the layer of metal grains near the surface of the die-casting part is finer and finely arranged. Improve surface hardness. The tensile strength of die castings can be 25%-30% greater than that of sand castings, but the elongation is reduced.

6. The production efficiency of die-casting is very high: the production process of zinc-aluminum die-casting is easy to be mechanized and automated. Usually, the cold chamber die casting machine can die-casting 600'I00 times every eight hours on average, while the hot chamber die casting machine can die-casting 3000-TWO times every eight hours on average. Since the die-casting process is mainly completed on the die-casting machine, it is easy to automate the production process.

7. Thin wall and shape of the casting. Complex and clear summary: the small wall thickness of aluminum alloy die castings can be 0.3mm, the aluminum alloy die castings can be 4.5mm, the diameter of the small casting hole can be 0.7mm; the small pitch of the castable thread is 0.75mm.

Pусский

Pусский Español

Español