The trimming die is to cut the gate, flash, and overflow from the casting. The vast majority of die castings must be trimmed. The trimming method is determined according to the size of the casting, the type of casting alloy, and the number of castings that need to be trimmed. Regardless of the method used, it is important to realize that in most cases the number of castings that are trimmed is extremely large, and the trimming process must be able to keep up with the high productivity of the die casting machine. The easiest way to trim the edges is to remove the unwanted parts of the casting by hand. For small castings, this will break the gate, flash and overflow groove. For large castings, a hammer must be used to knock off the useless parts. Broken edges can be smoothed with a grinding wheel, but areas that cannot be ground by a grinding wheel will need to be filed by hand.

In order to remove the useless parts of castings, various measures should be taken in the design stage. The thickness of the gate and the interface thickness of the overflow groove should be small so that they can be easily disconnected, and the axial shrinkage of the gate area should be minimized. However, the thickness of the gate should not be too thin, so as not to affect the quality of the casting. Ingates should be located in the straight part of the profile as much as possible, because curved ingates, such as those on cylindrical parts, are more difficult to break. This is also true for ingates that run along curved parting surfaces.

Sometimes the inner gate of the die casting is very thick, which reduces the filling speed and filling time. This alleviates the die erosion problem that occurs with the die casting process—a persistent problem due to high molten metal and dies temperatures. The high strength of the casting and the use of a thick sprue means that a band saw must be used to sprue the casting.

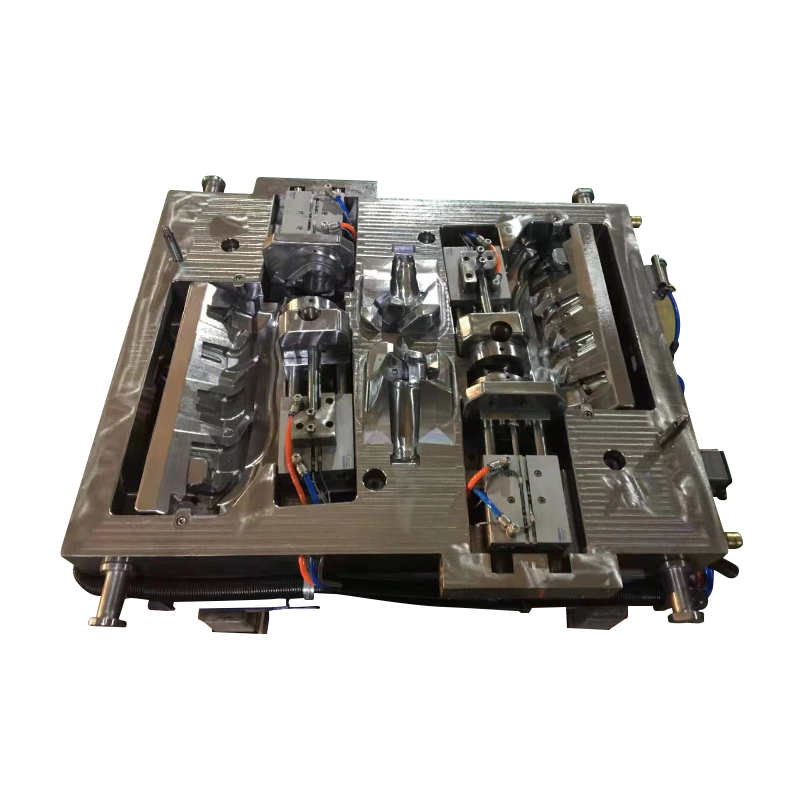

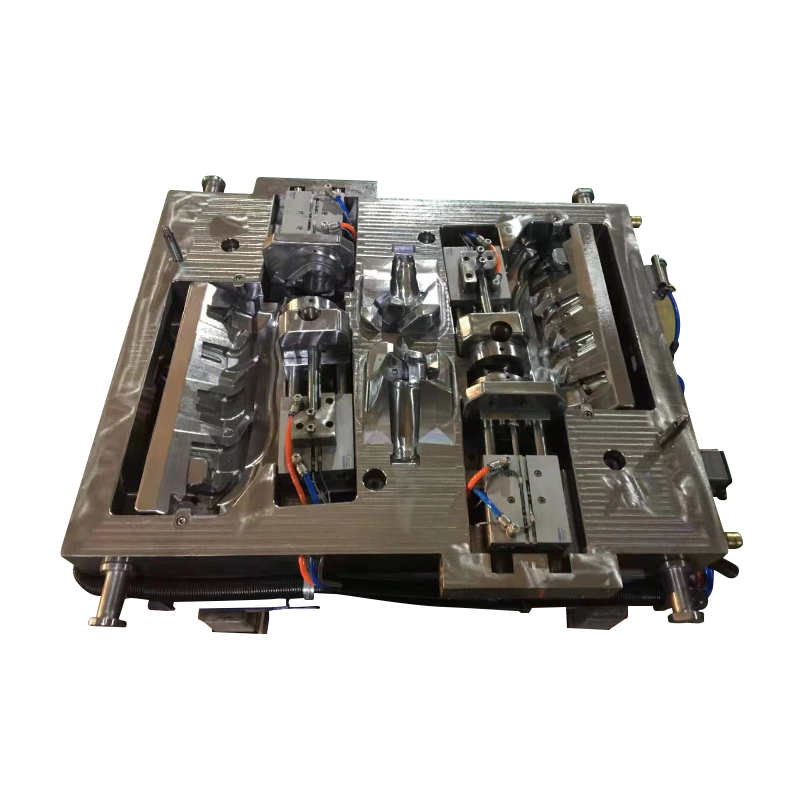

Trimming presses are used for large numbers of complex castings, forcing the castings through trimming dies. In order to make the trimming die as simple as possible, the parting surface should not be stepped if possible. Trimming presses are often located close to the die casting machine. This allows operators, casting pickers, or robots to place castings directly into the press when removing castings from the die casting machine. Failure of either the trimming press or the trimming die means that the die-casting machine also stops working unless an alternative method is immediately provided to remove the gate and flash from the casting when the press or trimming die is repaired.

Pусский

Pусский Español

Español