High productivity

The machine has high productivity. For example, the domestic JIII3 horizontal cold air die-casting machine can die-cast 600-700 times on average in eight hours, and the small hot-chamber die-casting machine can die-cast 3,000-7,000 times on average every eight hours; Die-casting bell alloys have a lifespan of hundreds of thousands of times or even millions of times; it is easy to realize mechanization and automation.

Excellent economic effect

Due to the precise dimensions of the die-casting parts, the surface is smooth and clean. Generally, it is not used directly without mechanical processing, or the processing volume is very small, so it not only improves the metal utilization rate but also reduces a lot of processing equipment and man-hours; the price of castings is easy; combination die-casting can be used to make other metal or non-metallic materials. . Saves both assembly man-hours and metal.

Development of Precision Die Casting

There is a big gap between the quality and performance level of domestic die-casting machines in China and foreign advanced industrial countries. However, due to the wide distribution of die-casting parts, from transportation energy to household appliances, to the daily industrial products of thousands of households, there are all kinds of die-casting parts. The existence and the market requirements of these die castings are different, which brings space to the domestic die casting machine market, especially for medium and small die casting machines, this space may continue for a long time. This provides a favorable opportunity for accelerating the improvement of the quality and performance of domestic die-casting machines. As the processing base of the basic industry of the world machinery industry, especially the processing base of die castings, China has undoubtedly brought good opportunities to the industry, and also stimulated the improvement of the quality of basic products in my country, requiring the quality and performance of machinery and equipment to be synchronized with the Enter.

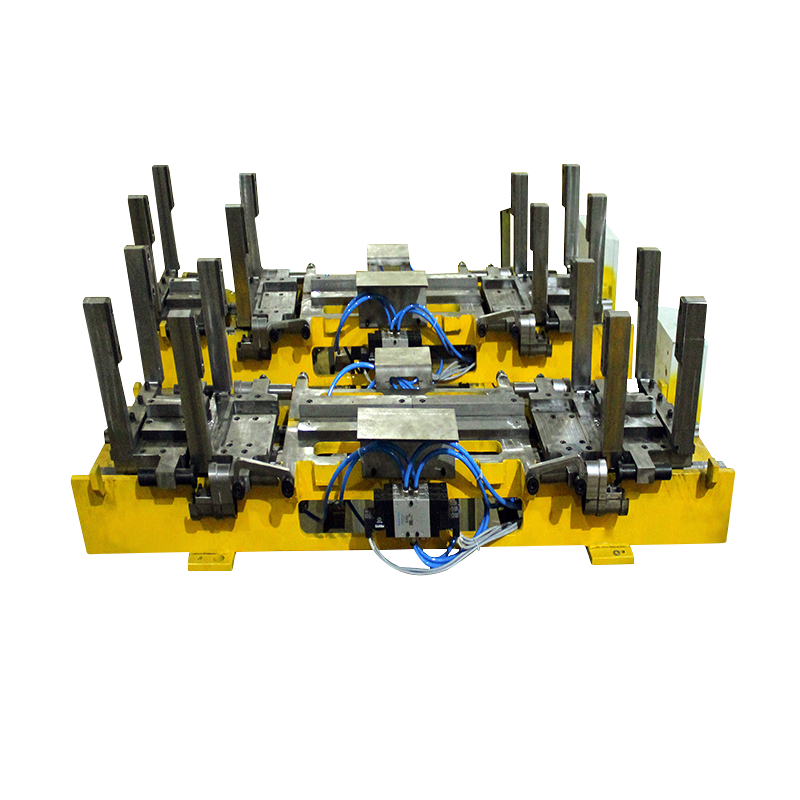

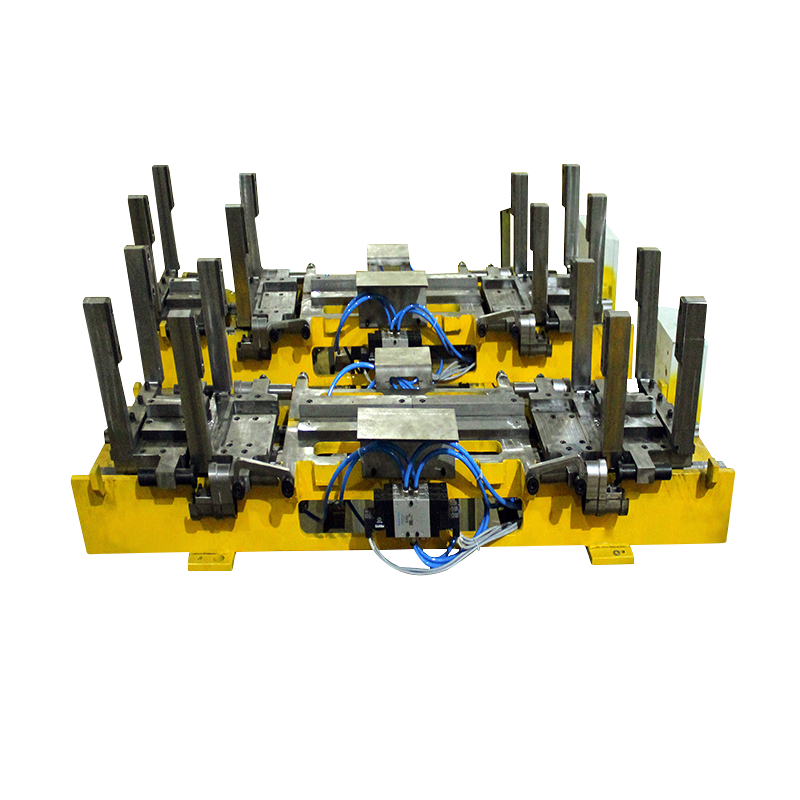

Zinc Alloy Precision Die Casting

It is a precision casting method. The dimensional tolerance of die castings cast by die casting is very small and the surface accuracy is very high. In most cases, die castings can be assembled and applied without turning. Threaded parts Can also be cast directly. Small parts such as general camera parts, typewriter parts, electronic computing devices, and ornaments, as well as complex parts of vehicles such as automobiles, locomotives, and airplanes, are mostly manufactured by die casting.

Pусский

Pусский Español

Español