1) Only one end enters (exhausts) air, the structure is simple, and the air consumption is small.

2) Using spring force or diaphragm force to reset, a part of the compressed air energy is used to overcome the spring force or diaphragm tension, thus reducing the output force of the piston rod.

3) Springs, diaphragms, etc. are installed in the cylinder, and the stroke is generally shorter; compared with the double-acting cylinder of the same volume, the effective stroke is smaller.

4) The tension of the return spring of the cylinder and the diaphragm changes with the magnitude of the deformation, so the output force of the piston rod changes during the travel.

Due to the above characteristics, single-acting piston cylinders are mostly used for short strokes. The thrust and movement speed are not demanding occasions, such as air lifting, positioning and clamping devices. This is not the case for single-acting plunger cylinders, which can be used in long strokes and high loads.

2) Using spring force or diaphragm force to reset, a part of the compressed air energy is used to overcome the spring force or diaphragm tension, thus reducing the output force of the piston rod.

3) Springs, diaphragms, etc. are installed in the cylinder, and the stroke is generally shorter; compared with the double-acting cylinder of the same volume, the effective stroke is smaller.

4) The tension of the return spring of the cylinder and the diaphragm changes with the magnitude of the deformation, so the output force of the piston rod changes during the travel.

Due to the above characteristics, single-acting piston cylinders are mostly used for short strokes. The thrust and movement speed are not demanding occasions, such as air lifting, positioning and clamping devices. This is not the case for single-acting plunger cylinders, which can be used in long strokes and high loads.

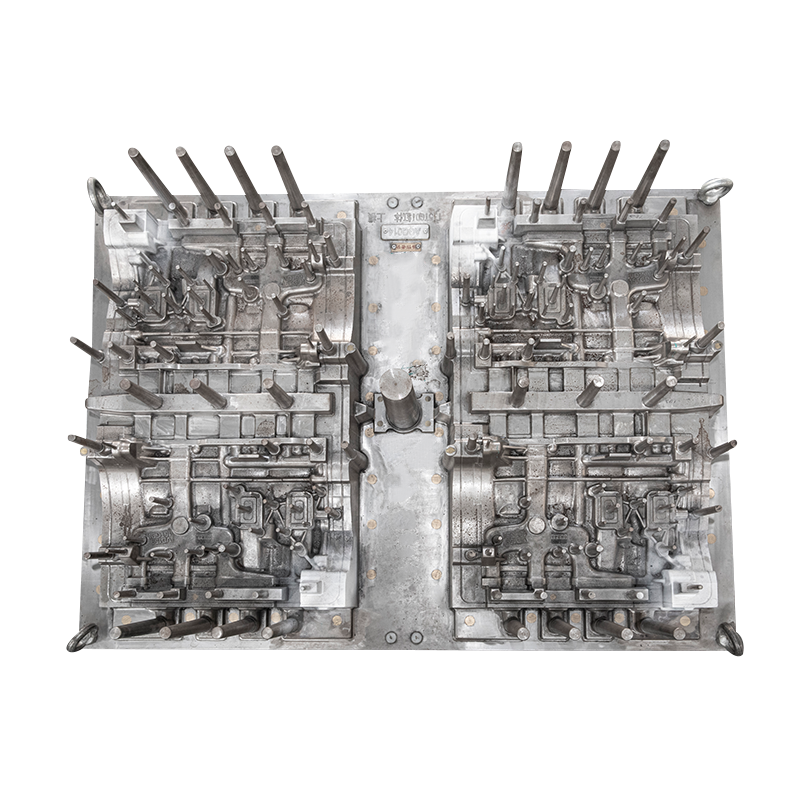

Xiangshan Lianqiang Automobile Mould Co., Ltd. is professional Automotive Mould Manufacturers and custom Engine Mould Factory in China. Its product types include Productionline, Cylinder, Cylinder Head, Turbine Volute, Sand Core And Fixture, Parts and peripheral configurations. If you want to learn more about Cylinder related information, please visit Xiangshan Lianqiang Automobile Mould Co., Ltd.

Pусский

Pусский Español

Español