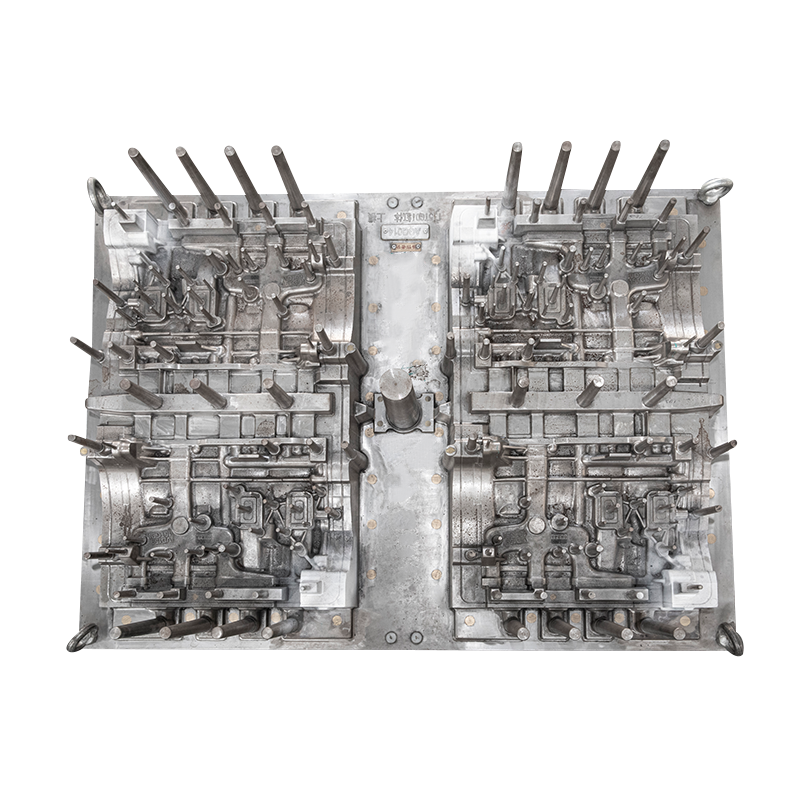

There are many types of mold casting, including gravity casting molds and high-pressure die casting molds (die-casting). So what is the difference between these two casting processes?

There are three requirements for the material of the gravity casting mold. The accuracy of the size can be relatively fine, and the wall thickness must be above 4mm. Of course, some local positions can be below 4mm. Moreover, the gravity casting mold product has a high degree of freedom, is relatively mature, has a high production efficiency, and a solid solution is also relatively good.

Compared with gravity casting molds, high-pressure die casting molds are inferior in mechanical properties. The liquid is too late to absorb and cannot be solid solution treated. The wall thickness is greater than 10mm, which is not conducive to production and the cost is relatively high. But its life span is relatively high, about 80,000/mold times.

Gravity casting is one of the main ways to obtain mechanical casting product blanks. Although advanced equipment is an indispensable factor to ensure product quality, the role of molds in the casting process is also very important. Especially for aluminum alloy auto parts manufacturers, the accuracy and durability of molds have a very obvious impact on product quality.

In the social production process, gravity casting has gradually been accepted by major automobile and daily necessities manufacturers due to its advantages over other casting methods, and its proportion in the market has gradually increased.

Pусский

Pусский Español

Español